Targetry and

Beam lines

ACSI offers a full range of radioisotope production solutions, including liquid, gas and solid targets, various beam line options and integrated systems for radioisotope production

Targets

18F Targets

View DetailsTarget made of aluminum and niobium, Havar window foil

Small Target (SMT)

Volume: 1.8 mL

Operating current: 55-65 µA

Max Current: 80 µA

Standard Target (STT)

Volume: 2.5 mL

Operating current: 70-80 µA

Max Current: 100 µA

Large target (LT)

Volume: 3.8 mL

Operating current: 80-100 µA

Max Current: 120 µA

Cooling: water, 3-6 lpm & helium, 50-100 slpm

Nuclear reaction: 18O(p,n)18F

Target material: (18O)water

Target product: 18F-

13N target

View DetailsTarget made of aluminum (standard) or aluminum and niobium (large), Havar window foil

Standard Target (STT):

Volume: 1.8 mL

Operating current: ~35 µA

Max Current: 40 µA

Large Target (LT):

Volume: 2.5 mL

Operating current: ~80 µA

Max Current: 100 µA

Cooling: water, 3-5 lpm & helium, 50-100 slpm

Nuclear reaction: 16O(p,α)13N

Target material: 3-7 mmol EtOH in water

Target product: 13NH4OH

Yield (EOB): 20 min irradiation

STT (mCi): 300

LT (mCi): 1000

68Ga target

View DetailsNuclear reaction: 68Zn(p,n)68Ga

To avoid co-production of 67Ga, cyclotron should be operated at 13-14 MeV (TR-19 cyclotron doesn’t require use of the beam energy degrader). Target windows will provide additional beam energy reduction to ~12 MeV.

Irradiation | 68Ga**, GBq (liquid)

30 min | 3

1 hour | 5

2 hours | 8

** The maximum irradiation current for 68Ga is limited to 40µA

H215O Target

View DetailsTarget made of aluminum and niobium

Volume: 26 mL

Length: 138 mm

Diameter: 15.5 mm

Operating current: 20-25 µA

Max Current: 25 µA

Process

Irradiation time 6 min

Process time < 2 min

In-target (15O)water production

Automated 15N2 recovery and

(15O)water delivery system

Cooling: water, 3-5 lpm & helium, 50-100 slpm

Nuclear reactions: 15N(p,n)15O; 14N(d,n)15O

Target material: 15N2/H2(5%) gas mixture

Target product: (15O)water

Yield: > 500 mCi (15O)water delivered up to

100 m distance

11C Targets

View DetailsTarget made of aluminum, Havar window foil

11CO2-Target

Volume: 58 mL

Length: 187 mm

Start Diameter: 12 mm

End Diameter: 26 mm

Operating current: 30-40 µA

Max Current: 50 µA

11CH4-Target:

Volume: 94 mL

Length: 187 mm

Diameter: 25.4 mm

Operating current: 30-40 µA

Max Current: 50 µA

Cooling: water, 3-5 lpm & helium, 50-100 slpm

Nuclear reaction: 14N(p,α)11C

Target material: (2-5% H2/N2) / (0.1-0.5% O2/N2)

Target product: 11CH4 / 11CО2

Target | Yield (EOB) 30 min irradiation /Ci

11CO2 | 4.0

11CH4 | 1.5

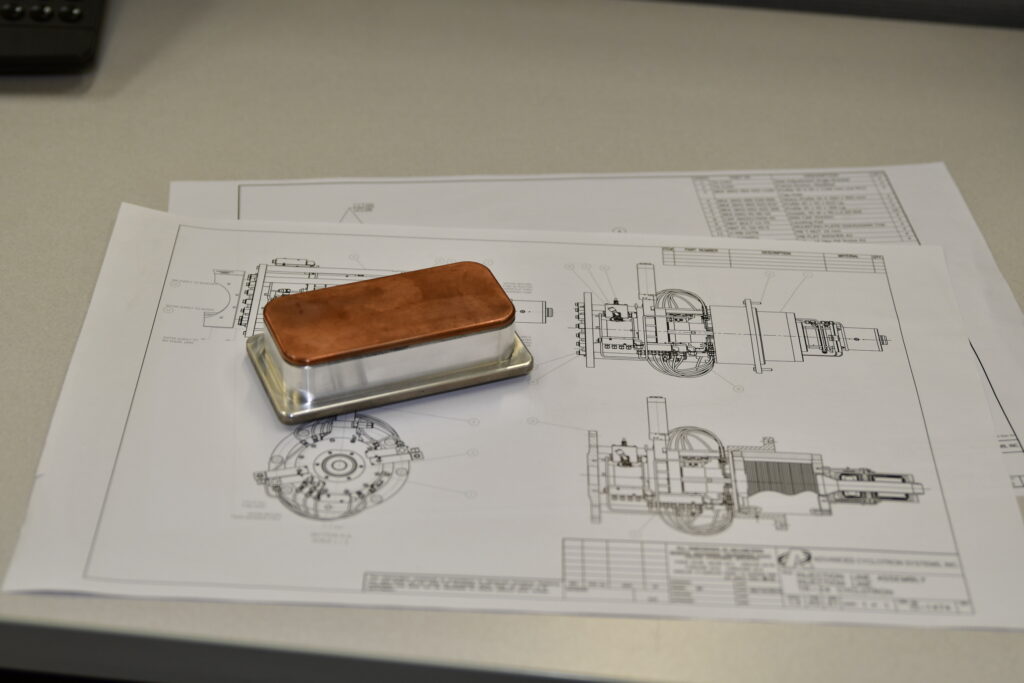

Custom Systems

View DetailsOver the years ACSI has been involved in numerous projects in targetry and radioisotope production system development. We have worked with research labs, universities and commercial partners, developing innovative solutions, improving existing technologies and setting new records.

If you have any ideas or would like ACSI to develop a customized target solution for your facility, we are open to discussion and ready to work on new and exciting projects.

Standard Solid Targets

View Details90° solid target holder

Operating current: 20-70 µA

Max current: 80 µA

Target products: Cu-64, Ga-67, Ga-68, Y-86, Zr-89, In-111, I-123, I-124, Tc-99m

Target disk size: Ø 24 mm x 2 mm

Effective target size: Ø 10 mm

Manual loading of the target disk in the target holder; pneumatic release of target into lead container

Optional upgrade

A solid target feeder can be placed on top of the solid target holder. It can hold up to 6 pre-plated solid targets at a time, allowing for rapid feeding of new targets without manual intervention required.

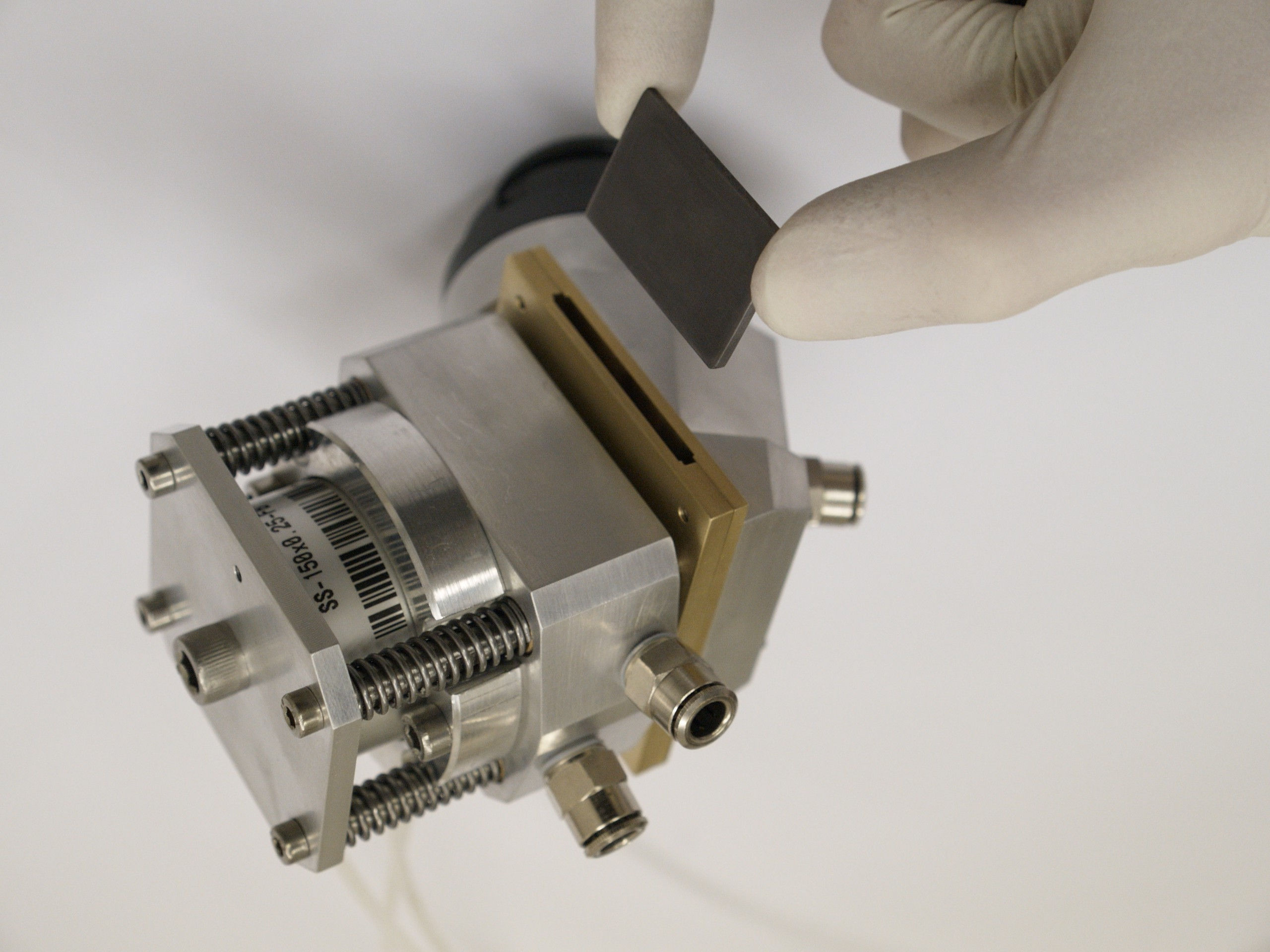

Custom Solid Targets

View Details30° solid target holder

Operating current: 40-90 µA

Max Current: 100 µA

Target materials

64Ni, 66Zn, 67Zn, 76Se, 86Sr

89Y, 123Te, 124Te, 111Cd, 100Mo

Target preparation

Electroplating

Deposition

Melting

High Pressure Pelletization

Electrophoresis

Target plate size: 24 mm x 40 mm x 2 mm

Effective target size: 10.5 mm x 20.5 mm ellipse

Manual loading of the target disk in the target holder; pneumatic release of target into lead container

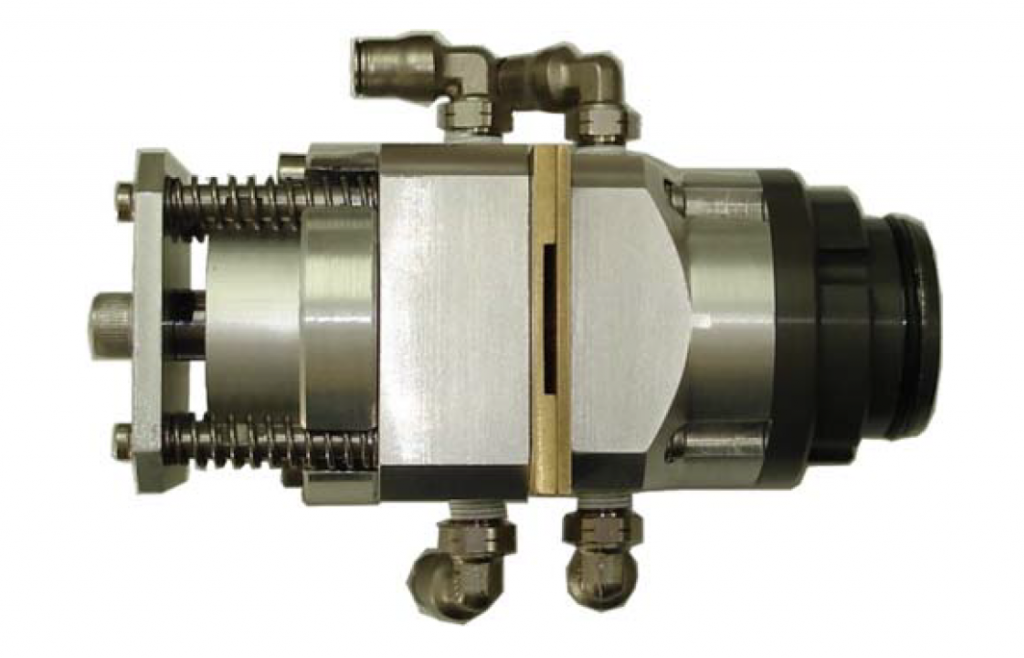

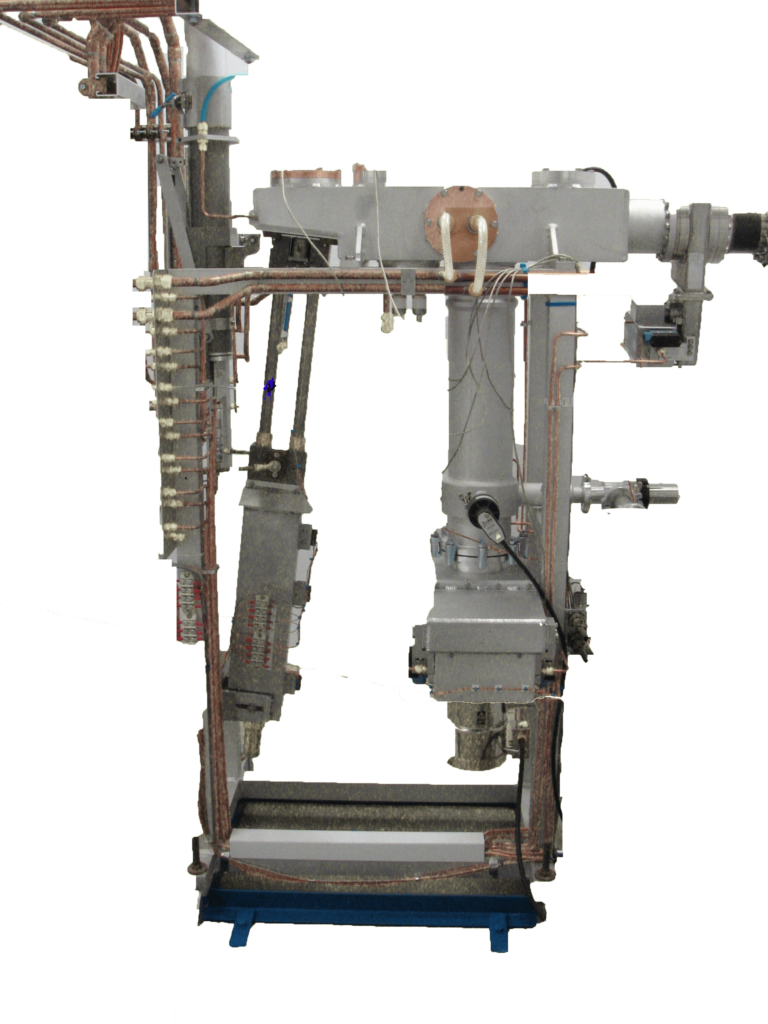

Solid Target Station

View DetailsThe ACSI High Current Solid Target Station (HCSTS) is a fully automated, remotely operated, robust targetry system, designed to handle a high current particle beam and capable of producing large quantities of medical isotopes.

The HCSTS can be integrated into a TR-24, TR-FLEX or a TR-30 cyclotron system.

Normal operating current up to 500 µA (600 µA max).

Collimators shape beam to desired size.

The landing terminal sends and receives the “rabbits” that transport the target between the target station and hot-cell terminal.

Gas Target Stations

View DetailsAllows production of ultra-pure Iodine-123 in Curie quantities by irradiation of highly enriched Xenon-124 with 24 or 30 MeV protons.

The two reactions leading to I-123 are: 124Xe(p,2n)123Cs→123Xe→123I and 124Xe(p,pn)123Xe→123I.

Can be operated up to 150 uA of beam current.

Compatible with the TR-24, TR-FLEX and TR-30 cyclotrons.

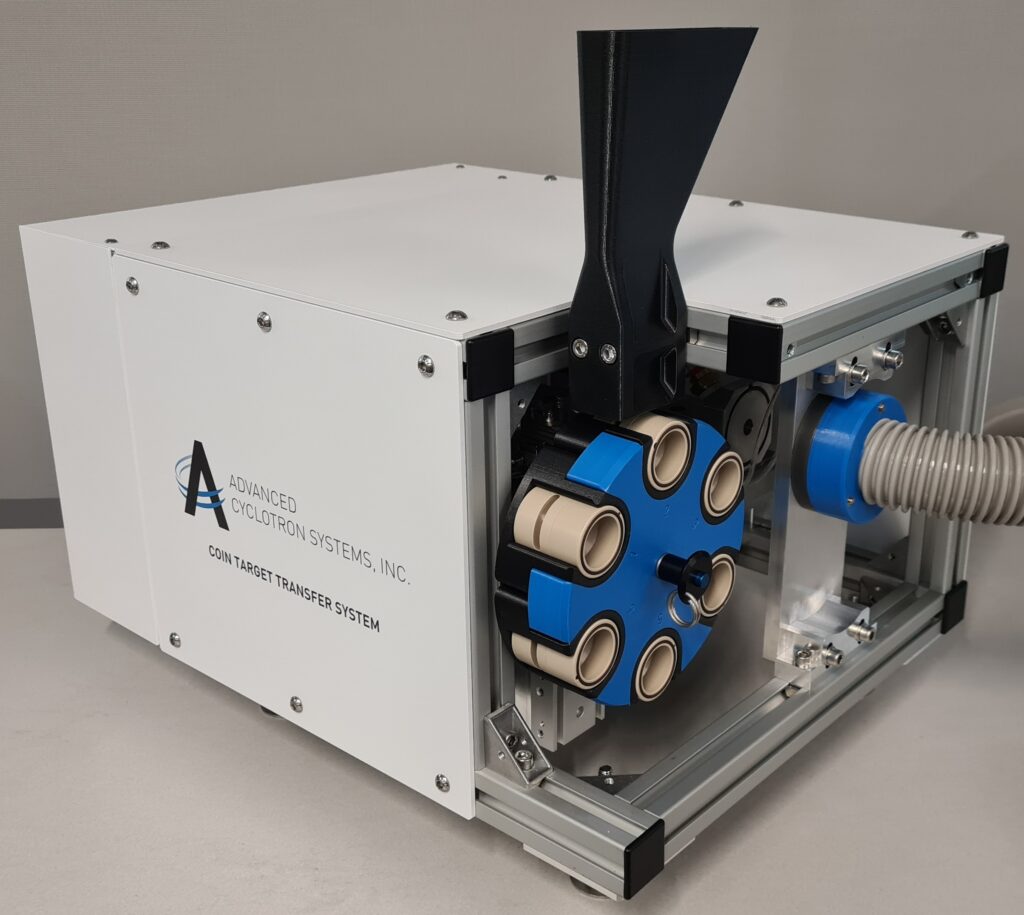

Solid Target Transfer

View DetailsOnce irradiation of the solid target (coins) is completed, the irradiated coin is automatically loaded into a transport rabbit, pre-loaded into the transfer station.

The transfer station is placed below the irradiation unit, either under the target selector or under a single port irradiation unit, depending on the ACSI cyclotron configuration.

The transfer station’s cartridge holds up to 6 rabbits, allowing for 6 targets to be irradiated and transferred before being reloaded.

Each rabbit can securely hold a single irradiated target while it is rapidly transferred to the hot cell via a compressed air tube to distances up to 30 meters away. Extended distances can be reached by using booster units.

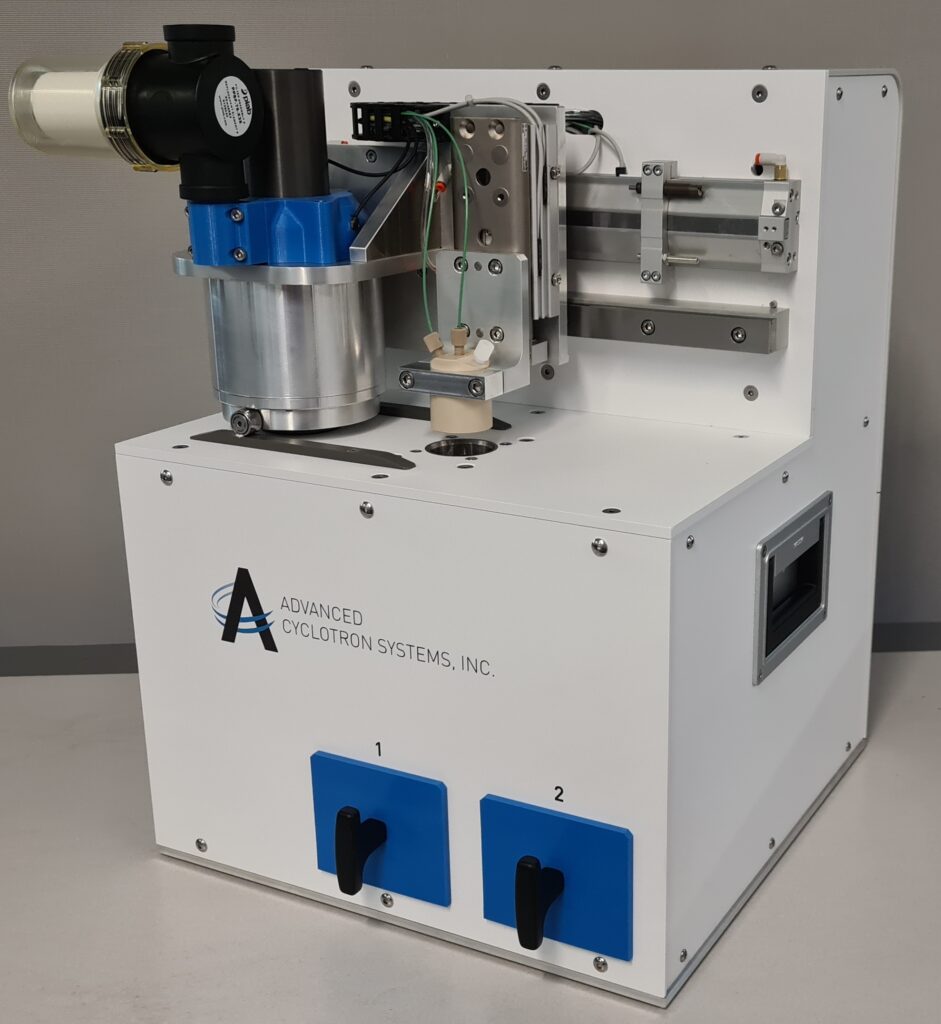

Solid Target Processing

View DetailsA receiving unit inside the hot cell, automatically catches the incoming rabbit (see Solid target transfer) and moves it into the target dissolution position. The rabbit body is a sealed vessel, made from PEEK, where the target dissolution procedure can take place.

The dissolution unit must be connected to an external chemical module*, in order to receive the required reagents for dissolution and for further transfer of the dissolved target material for purification and recovery.

Following an automated cleaning process, the spent rabbits are released into a storage drawer located inside the hot cell for cool down and future reuse.

*ACSI can provide this module if requested by customer

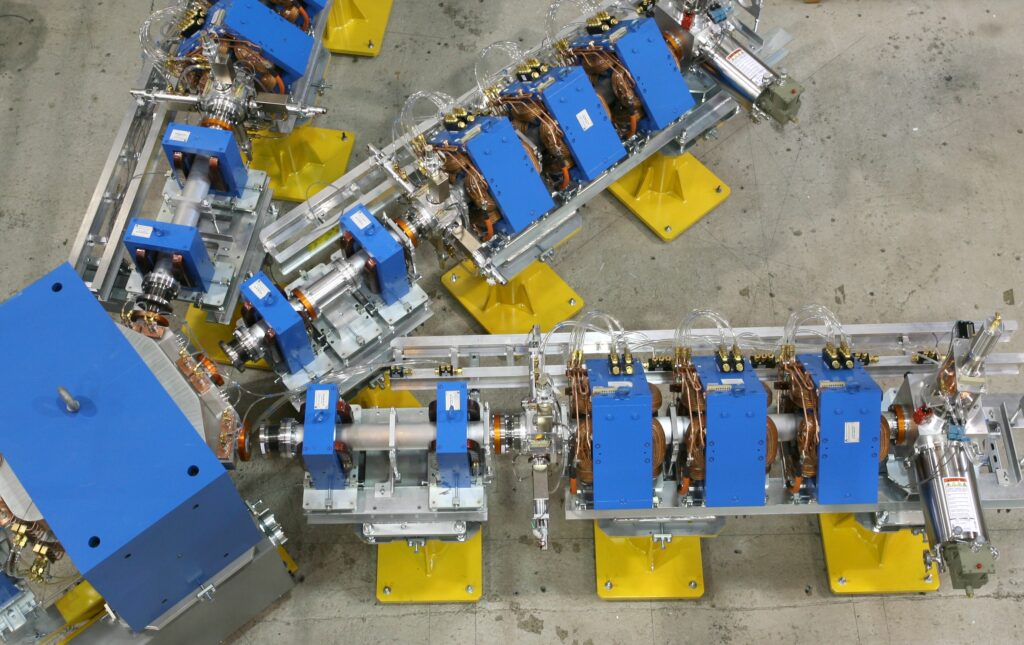

Beam Lines

To take full advantage of TR cyclotrons production capabilities equip your cyclotron with standard or custom beam line.

TR-19 Beam Lines

View DetailsThe TR-19 cyclotron can be equipped with one or more external beam lines. The vertically oriented dipole magnet allows to adjust the angle of the extracted beams of different energies and also serves as a vertical switching/steering magnet adjusting the beam trajectory through the beam lines. This dipole magnet can be equipped with one or two exit ports that allow for installation of two beam line branches: one oriented horizontally and a second one downward at a 25 degree angle.

Beam lines typically have two focusing magnets and a set of protection collimators. Additional elements can be added to the beam lines to satisfy end user requirements.

Each beam line branch can be equipped with one of the following options:

Option 1

3- or 4-port target selector for irradiation of regular targets, liquid, gas, or solid.

Option 2

Single target port. Typically used for installation of solid target in combination with automated solid target transfer system.

Option 3

High current solid target station. This option allows the end user to take full advantage of the high current capability of the TR-19 cyclotron and to irradiate solid targets with over 300 µA current.

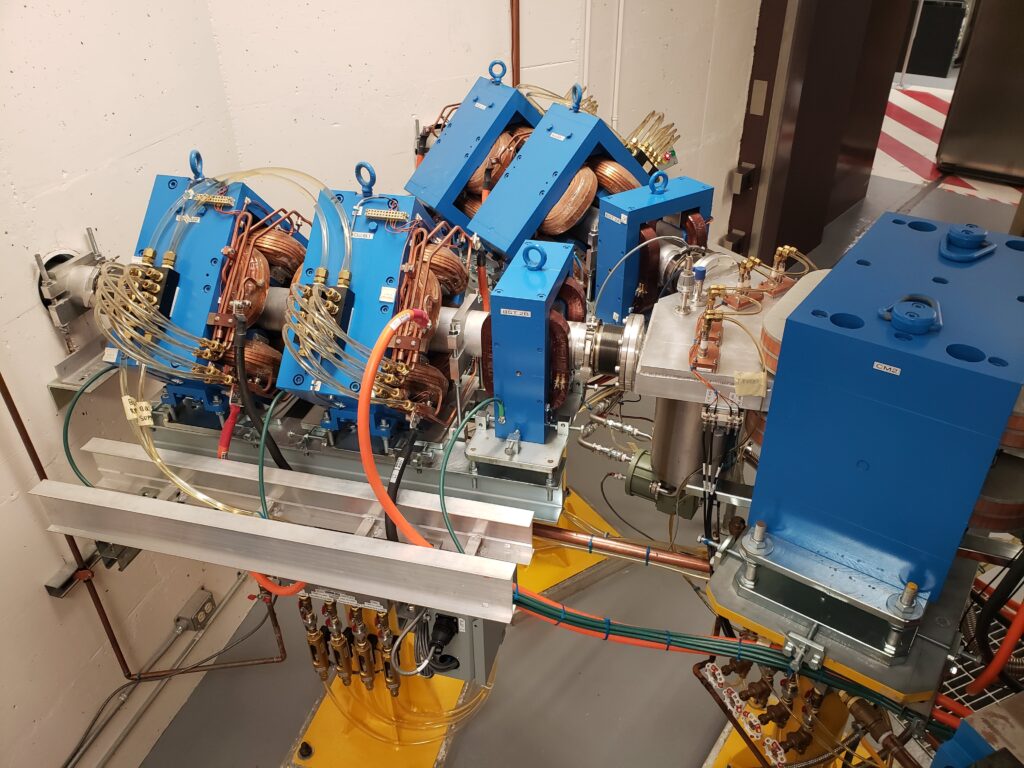

TR-24 and TR-Flex Beam Lines

View DetailsThe TR-24 and TR-FLEX cyclotrons can be equipped with one to six external beam lines. Typically, the TR-24 and TR-FLEX are installed with 2 or 4 beam lines, where Y-shaped beam lines are located on the opposite sides of the cyclotron. Each Y-shaped beam line has two branches.

A switching dipole magnet is installed at the beam exit port. By switching polarity of this magnet, the extracted beam can be directed to one of the two branches and delivered to the target system installed at the end of the beam lines. Each beam line has a set of protection slits, collimators, focusing and steering magnets. A vacuum pumping station, cryo-pump based, is shared between two beam lines.

The TR-24 and TR-FLEX cyclotrons can be equipped with a larger switching magnet allowing installation of three beam line branches.

Additional elements can be added to the beam lines to satisfy end user requirements.

Each beam line branch can be equipped with one of the following options:

Option 1

3- or 4-port target selector for irradiation of regular targets, liquid, gas, or solid.

Option 2

Single target port. Typically used for installation of solid target in combination with automated solid target transfer system

Option 3

High current solid target station. This option allows the end user to take full advantage of the high current capability of TR-24 and TR-FLEX cyclotrons and to irradiate solid targets with up to 500 µA current.

Option 4

High current gas target station for I-123 production

TR-30 Beam Lines

View DetailsThe TR-30 cyclotron can be equipped with one to six external beam lines. Typically, a TR-30 cyclotron is installed with 4 or 6 beam lines.

A switching dipole magnet is installed at the beam exit port. By switching the polarity of this magnet the extracted beam can be directed to one of the two branches and delivered to the target system installed at the end of the beam lines. The TR-30 cyclotron is often equipped with a larger switching magnet allowing installation of three beam line branches on each side of the cyclotron, making the total number of beam lines six.

Each beam line has a set of motorized protection slits, collimators, focusing and steering magnets, and an independent vacuum pumping station, cryo-pump based.

Additional beam shaping and diagnostics elements can be added to beam lines to satisfy the end user requirements.

Each beam line branch can be equipped with one of the following options:

Option 1

3- or 4-port target selector for irradiation of regular targets, liquid, gas, or solid

Option 2

Single target port. Typically used for installation of solid target in combination with automated solid target transfer system

Option 3

High current solid target station. This option allows the end user to take full advantage of the high current capability of the TR-30 cyclotron and to irradiate solid targets with up to 600 µA current.

Option 4

High current gas target station for I-123 production

Custom Beam Lines

View DetailsIn addition to our standard beam lines ACSI can offer customized beam line configurations to fulfill specific customer’s requirements.

Additional beam shaping and beam diagnostics elements can be added to the beam lines.

Contact us to discuss your specific beam line needs.

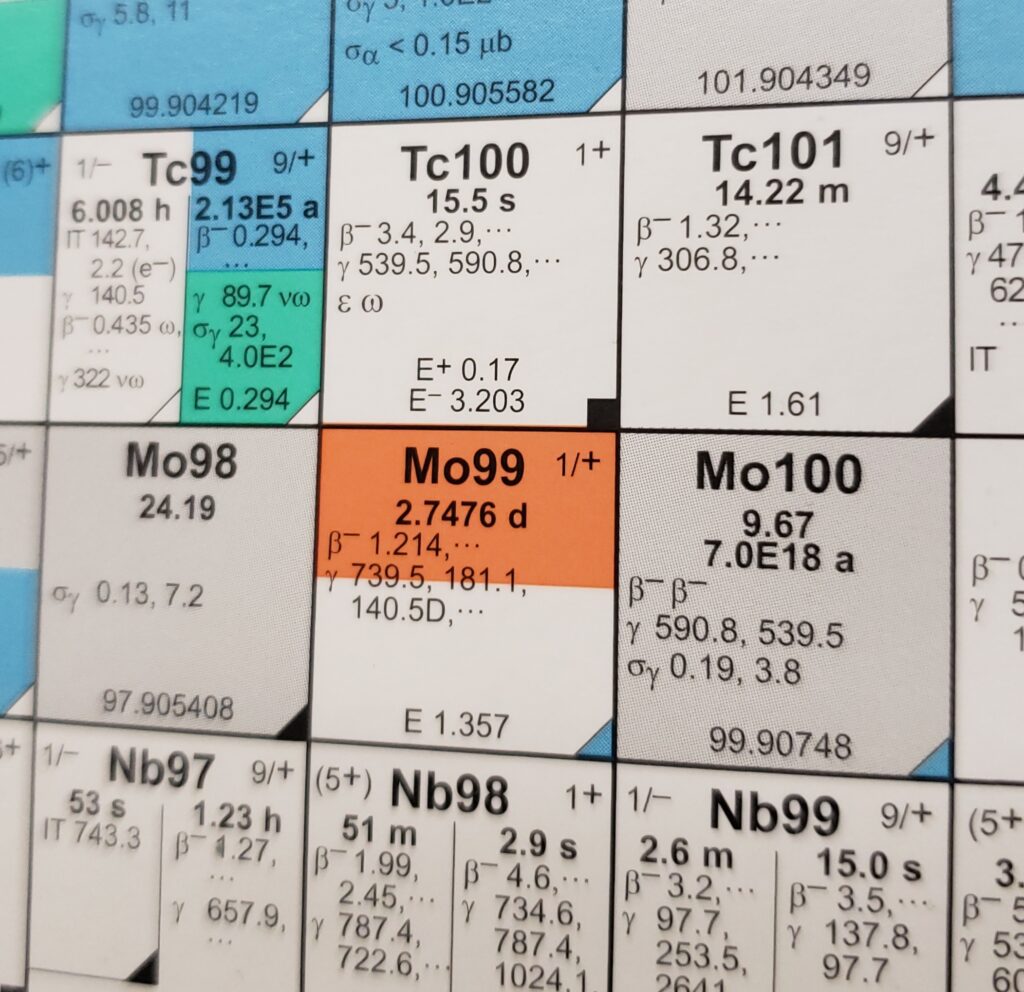

CYCLOTEC™ and CYCLOMOLY™

Rising numbers of diagnosed cancer cases has created an even higher demand for new discoveries in nuclear medicine. This will increase the demand for isotopes used in both PET and SPECT imaging procedures.

According to the OECD Nuclear Energy Agency, demand for medical isotopes will continue to grow, increasing the global market from $3.2 to $4.1 billion over the next 4 years alone.

Technetium-99m is the most commonly used medical isotope in the world, and the expected shutdown of the Chalk River Reactor in 2016 will further contribute to the global shortage of this key isotope.

At the forefront of Canada’s solution to this foreseen shortage is the use of commercially available cyclotrons like our TR-30, TR-FLEX, TR-24, TR-19 to produce this important isotope.

Along with our academic partners, we have developed a series of techniques that can produce enough technetium to satisfy Canada’s long-term requirement. We call cyclotron-produced technetium: CYCLOTEC™, and along with our Canadian partners, have established a national network of technetium-producing cyclotrons that will ensure the self-supply of CYCLOTEC™ and other medical isotopes across Canada.

CYCLOMOLY™ is Molybdenum-99 made on an ACSI cyclotron.

Molybdenum-99 can be made in large quantities on ACSI’s higher energy cyclotrons. The CYCLOTEC™ can be used as a generator to produce CYCLOTEC™.

Interested in learning more about CYCLOTEC™ and CYCLOMOLY™? Click on our brochure, or contact us directly at info@advancedcyclotron.com. We’ll be happy to answer your questions!